Published:

After 30 years of operation, DEK Construction, the largest company of the DEK Group and the most important player in the building materials market, is embarking on new trends. In addition to an e‑shop or a machine and tool rental service, they are working on building whole houses with 3D printers. Such projects need to be managed efficiently, which is why the entire team has been working with Freelo for over a year now.

“The construction industry is experiencing a gradual but significant evolution, especially in the digitalisation of the entire sector. We are actively responding to these challenges.“

DEK building materials meet new technological trends. This makes the work easier for themselves and their customers. In addition to keeping an electronic construction diary, they launched the DEK Drive service during the pandemic, which was so popular with clients that they still use it today. You order online, arrive at the designated place and pick up the goods without getting out of your car.

DEK also sees the future of the construction industry in 3D printing. According to DEK Construction, a robot can handle robotic bricklaying or 3D printed building construction three to four times faster than a human, which is why they are working intensively in their research centre to develop printers.

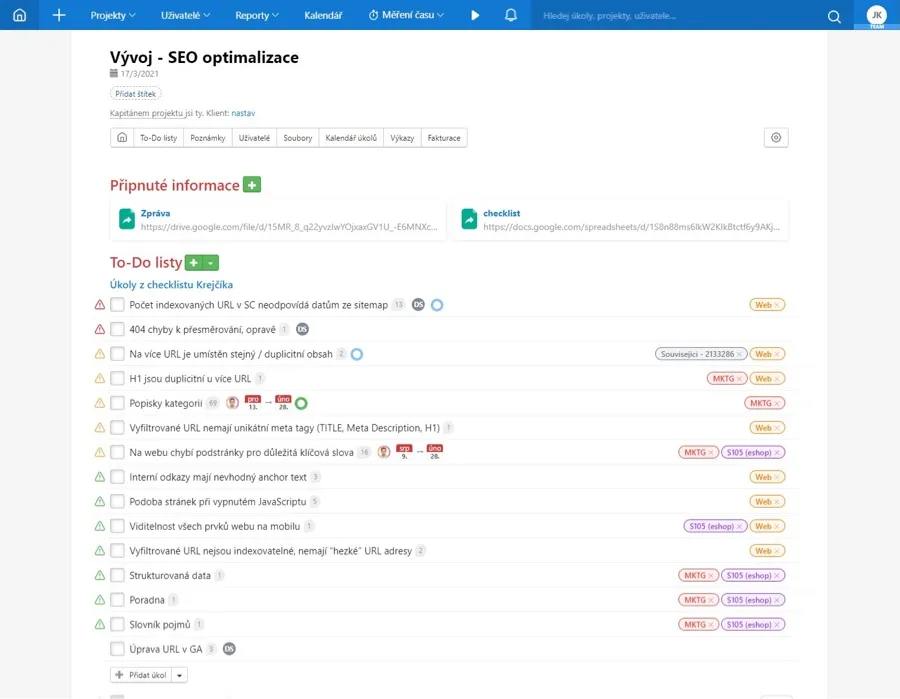

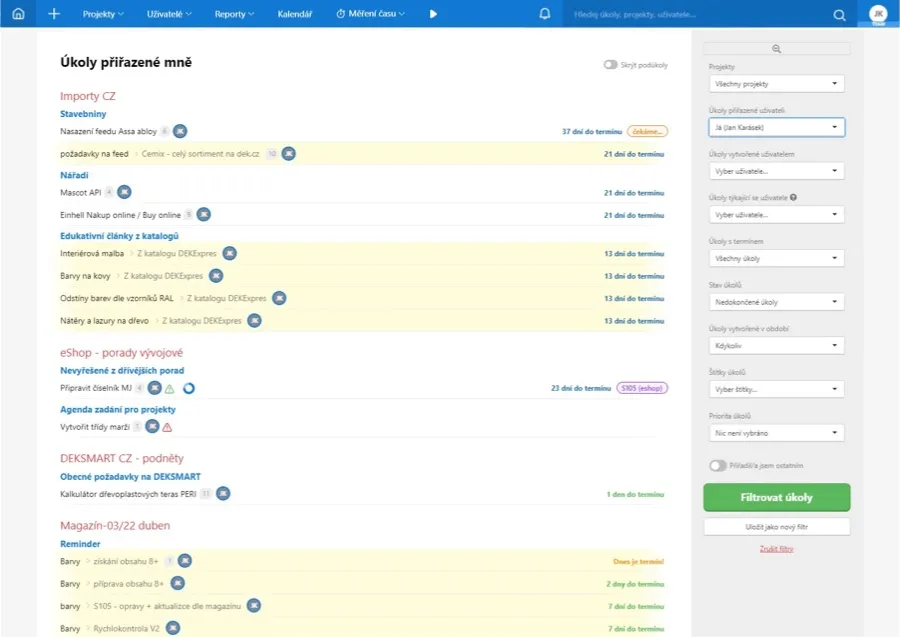

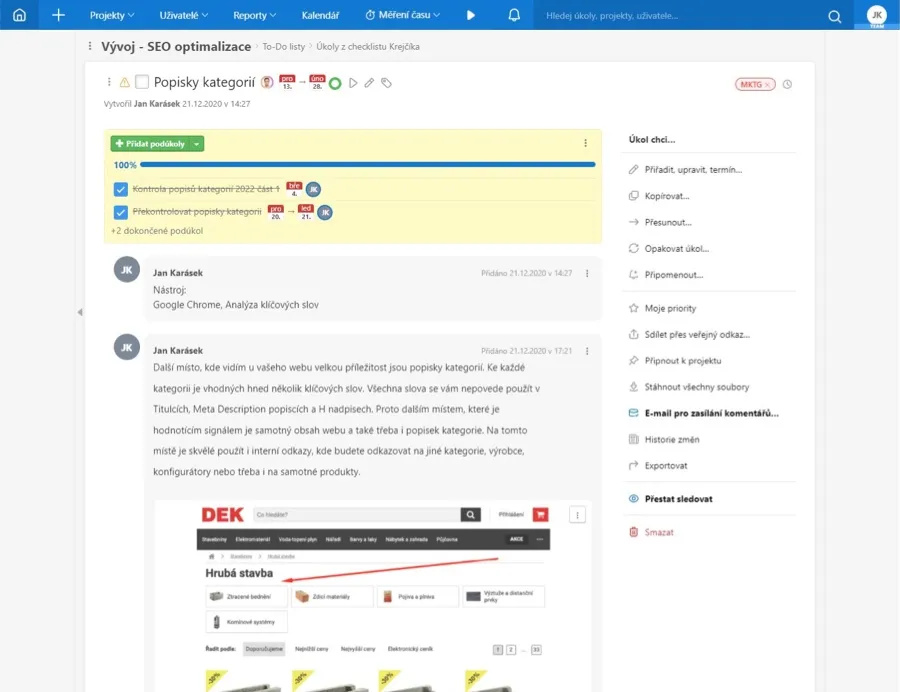

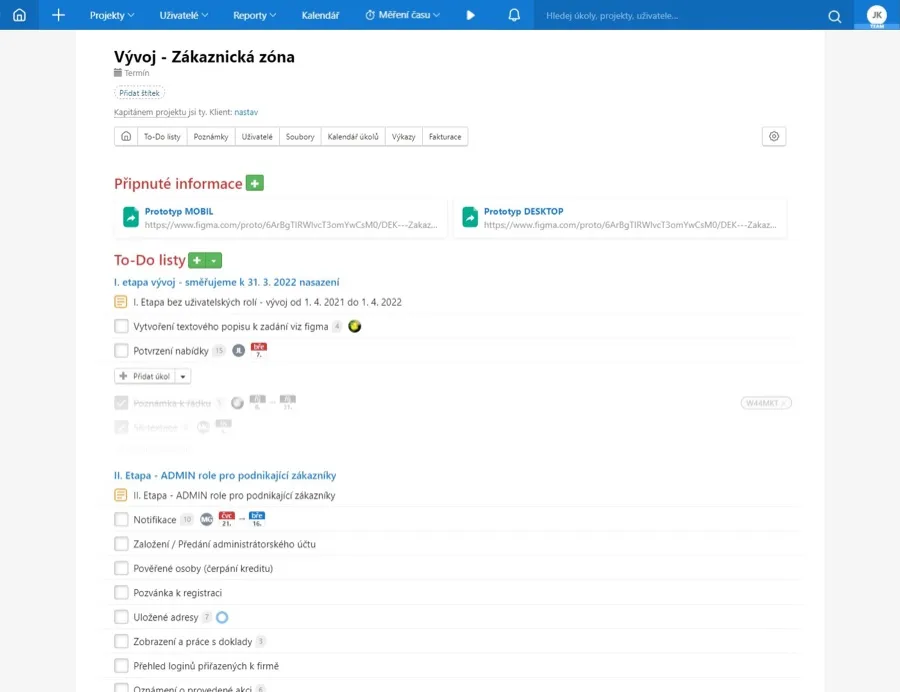

Jan Karásek's team at DEK Construction works from different parts of the Czech Republic. It was even more challenging to keep the whole team focused on specific tasks. But in Freelo, they learned „to break“ tasks down into smaller ones and work with their priorities. The short-term ones with a close deadline, which have the highest priority, cover up to 50 % of each team member's working capacity.

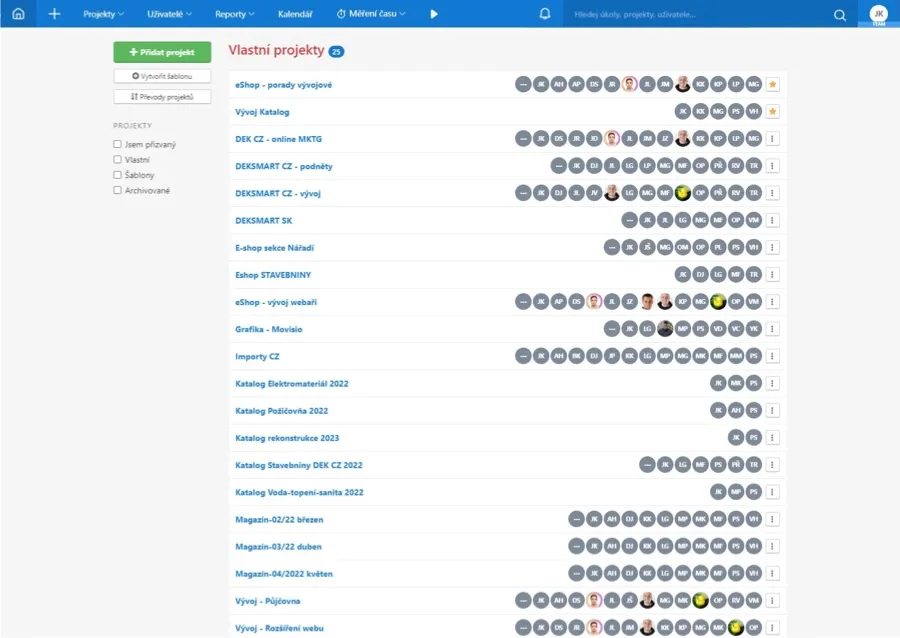

After more than a year in Freelo, DEK Construction has successfully completed 1.850 tasks in 55 projects.

“Before Freelo, we had to meet often and repeat what is currently the most important thing to implement and what can still wait. We spent most of the time on the phone and emailing, saying that now we need to do this and then that. Now we finally have a handle on it. In a surprisingly short time for me, we managed to find a way to structure the different tasks in Freelo.“

“After a year of using Freelo, we can't imagine working without it. Freelo needs to be absorbed into the workflow just like email. In short, you come to work and turn on your email together with Freelo.“

The first steps in implementing any new software in a company are never easy. But once you understand how to work with the system, it's easy. At DEK, they relied on advice from Freelo's instructional videos, then started trying out the application virtually.

“We ended up deleting the first project completely because we reached the end of the Freelo structure. So we started again and are now fully integrated into Freelo.“

DEK Construction know from their experience that a poorly thought-out project specification only leads to an overpriced product that has to be redesigned several times. They use Freelo for detailed planning of processes and scenarios, mindmaps help with visualisation, and complex projects with many links and connections are planned in a Gantt chart, which will soon appear in Freelo.